How To Clean And Pack Wheel Bearings and Save Hundreds of $$

Everything we drive has wheel bearings. Whether it’s our project truck, classic car, minivan, trailers, or ATVs, they all have wheel bearings. You can save a lot of money by learning how to clean and pack your own wheel bearings. It’s an easy job that only takes a couple of hours and a tub of wheel bearing grease.

How do you clean and pack wheel bearings?

- Lift truck and remove wheel

- Remove dust cap, cotter pin and castle nut

- Remove hub

- Remove bearing and seal

- Clean bearings in solvent

- Pack grease into bearings

- Assemble bearings and seals on hub

- Attach hub to spindle

- Mount wheel and lower truck

Cleaning and packing the bearings on our vehicles is an easy and money saving job we can do in less than two hours. Follow along as we explain this process in detail.

How To Clean And Pack The Bearings

Step 1 – Lift the truck: Park your truck on level ground, set the park brake, chock the rear wheel, jack it up and put the jack stands under the frame. Check that the truck is stable before continuing.

Step 2 – Remove the wheel: With the truck jacked up and on jack stands remove the wheel that you will be cleaning and packing the bearings on.

Step 3 – Remove the hub: Using the flat screwdriver pry off the dust cap and set aside. Next remove the cotter pin and set it in the dust cap. Undo the castle nut and set it with the cap and cotter pin.

Step 4 – Remove the bearings: Slide out the front bearing and the washer with it. Slide the hub off of the spindle, then using a flathead screwdriver, be very careful and pry the inner seal out from the inside (backside) of the wheel hub.

Once you have removed the seal use a punch to remove the inner bearing from the hub. Place all the parts removed from the hub assembly together on a clean shop towel.

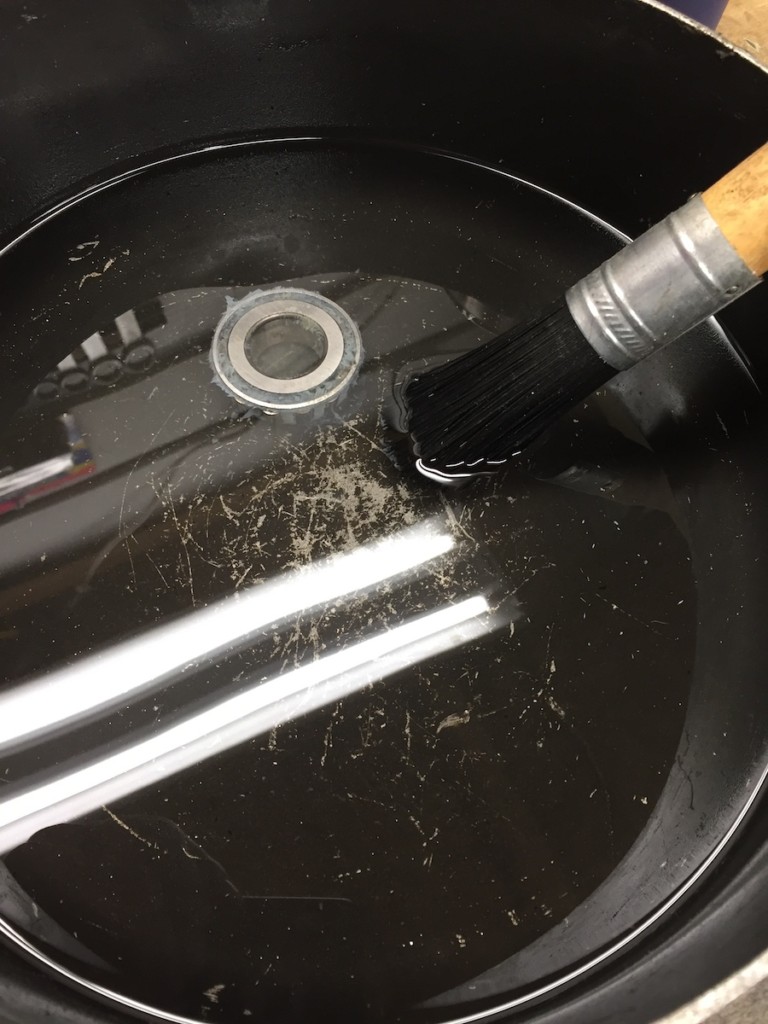

Step 5 – Clean the bearings: The best way to clean bearings is to immerse them in kerosene or a similar cleaner and roll them and brush them until all of the old grease is completely out of them.

Do this with all of the parts including the bearings, hub, nuts, washer, everything. When they are sufficiently clean spray them off with the brake cleaner then wipe them off with a clean shop towel and let them air dry on the towel. If you want to speed up the process you can blow all the parts dry using an air compressor.

Step 6 – Pack the bearings: Be certain you are using grease that is made for wheel bearings. NAPA Wheel Bearing Grease is well suited for packing wheel bearings. You need to work the grease every where into the bearings.

The best way to do this is to put a golf ball size clump on the heel of your hand and with your other hand tap the side of the bearing until it squeezes out the other side of the bearing. Repeat this technique all the way around the bearing until your certain the whole bearing is full, every nook and cranny.

Grease the spindle really well so that you have a visible amount all the way around the spindle.

Step 7 – Grease the hub and insert bearings: Grease the entire inside of the hub with at least a 1/8 inch thick coat. Install the inner bearing and install the new seal, being careful not to dent or bend it.

Step 8 – Install hub: Install the hub on the spindle being careful not to damage the inner seal. Install the outer bearing, washer and nut. Tighten the nut onto the spindle to where it is snug then back off 1/4 turn. Insert the cotter pin and replace the dust cap.

Step 9 – Finish the job: Install the wheel and tire, then snug the lug nuts tight. Drop the truck to the ground, then tighten the lug nuts to manufacturers torque specifications.

Step 10 – Lift the other side and repeat: After you have done both sides drive for 30 miles and check the torque on your lug nuts again.

Why Clean And Repack The Wheel Bearings?

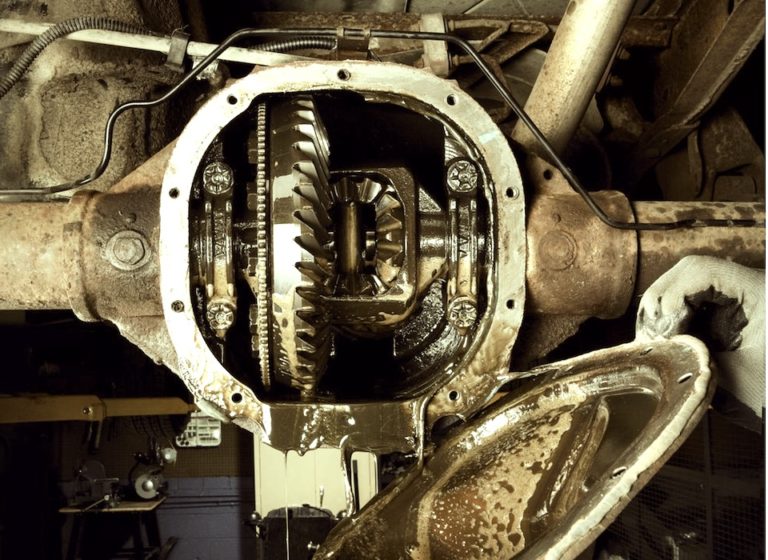

Even though wheel bearings are designed to last a lot of years, due to heat and the debris that can work its way into the center of the wheel, they will eventually need the old grease replaced in them with new grease. The old grease will lose its lubricity and major problems will follow. It is especially hard on the seals and bearings if you drive on a lot of dirt, gravel or wet roads as the moisture and dirt can work its way in to the bearings.

If your wheel bearings are not thoroughly cleaned and repacked with new wheel bearing grease, they will eventually wear out and fail. If one of the bearings breaks entirely, it can cause the wheel to completely come off of the vehicle. We have all seen a truck or trailer sitting on the edge of the road where it looks like the wheel has just fallen off.

When a wheel bearing is correctly packed with the recommended grease, it freely spins on the hub without creating excess heat. If the wheel bearing fails, it’s often due to there being a loss of lubricity inside the wheel bearing housing.

If you find excessive tire wear, consider replacing the wheel bearings as preventative maintenance. A grinding or rubbing noise coming from the tire area is a common symptom of worn bearings. Due to excess heat that has built up inside the wheel bearing, accompanied with the loss of lubricity, the wheel bearing will fail, and can result in the spindle snapping.

Grinding sounds are metal on metal contact. This sound will come from one side of the vehicle as bearings on each side of the truck don’t usually wear out at the same time. If you have this grinding, do not clean and pack the bearings, they need to be replaced.

When the hub and bearings are damaged, you will have steering wheel vibration. This means the wheel and tire are loose on the hub, creating a bouncing affect that causes the steering wheel to vibrate as your truck accelerates.

Tools And Supplies Required

Most of these tools and supplies we normally have around our shops and garages. Here is a list to gather up before beginning the job:

- Penetrating fluid

- Jack

- Hammer

- Jack stands (2)

- Brake cleaner (spray can)

- Wrench for lug nuts

- Bearing grease

- Flathead screwdriver

- Needle nose pliers

- Clean shop rags

- Kerosene for cleaning

- Adjustable wrench (large)

- Small catch pan

- Inner wheel seals

How Much Money Did I Save?

On a truck, it will cost between $250 and $400 on average to have your bearings checked, cleaned and repacked, or changed professionally (depending on your location and mechanic). Having trailer bearings packed is cheaper at $100 to $200. Most mechanics will try to up sell you with new brakes, rotors or other parts that they can include in the repair.

| Mechanic shop | DIY bearing job |

| $250 to $400 | Bearing grease, cleaner, seal $30 to $40 |

Final Thoughts

Its easy to do the cost comparison of a repair shop doing your repack and doing it yourself. You will save a minimum of $200, and can do your own inspection of your parts. I always have a concern of being upsold on parts that don’t really need to be replaced. I also like doing all the work on my C10 that I can do myself. Happy Trucking!

The Tool Box

Hers some tools that could come in really handy:

Related Topics

How do I know if my steering box is bad? Your truck may not drive straight and have a tendency to wander or veer to one side or the other. If you have excessive play in the steering wheel it can be caused by worn parts in the steering box. If your truck makes noises when turning like a grinding or thumping noise you may have a gear box problem. Another sign of a worn gear box is discolored oil.

How do I replace my power steering hoses? To remove the hoses, begin with the lower hose. It should be held onto the power steering pump by a hose clamp. You’ll need to loosen this with a screw driver and then pull the hose away from the pump, letting the fluid fall into the container. The second hose which is the pressure hose is easier when using a tubing wrench. Undo the lower end and let it drain into a pan. Reverse the steps to put on the new hoses.

One Comment

Comments are closed.