How Do You Service Your Truck’s Differential? A DIY Guide

One of the most overlooked maintenance items on your truck is servicing the rear end. It is tucked away, under and to the rear of your truck so it goes mostly unnoticed until there is a problem. Regular maintenance and service can keep you from those dreaded repair bills.

How do you service a truck differential?

- Park truck on flat surface

- Lift truck onto jack stands

- Degrease the outside of rear end

- Remove the cover and drain the lubricant

- Clean the housing and cover

- Replace the cover using a new gasket

- Refill with recommended lubricant

- Lower truck from jack stands

This is an important job that you can do on your truck that can be completed in less than two hours. I recently serviced mine, so read on as I go through these easy steps.

Changing this oil is just as important as changing your engine’s oil, and for the same reason. Metal-to-metal contact wears down surfaces and creates heat from friction, which inevitably weakens the gears and leads to failure. Checking and changing the differential oil in a light truck is actually pretty easy, and it’s only a bit more difficult in a car.

popularmechanics.com

Step 1: Park Truck on a Flat Surface

Never do any work on a vehicle without parking on a flat and level surface. This is a no-brainer way to avoid accidental injury or death. We might find it necessary to change a tire on a side hill or uneven gravel road somewhere, but when we have a choice, let’s be safe.

Leveling your truck will also make it easier to completely drain the old differential fluid, and to completely fill it with new fluid.

Step 2: Lift Truck Onto Jack Stands

If your truck sits low like mine you will need to lift it and set it on jack stands. Use the highest quality jack stands that you can afford. Check for stability before going under the truck.

Step 3: Degrease and Clean the Rear End

Scrape and spray off some of that old oil and grease that has built up on there over time so none of it gets inside and contaminates your new clean oil. It’s always a good idea to keep the underside of your truck clean so you can spot any potential problems and keep the rust down.

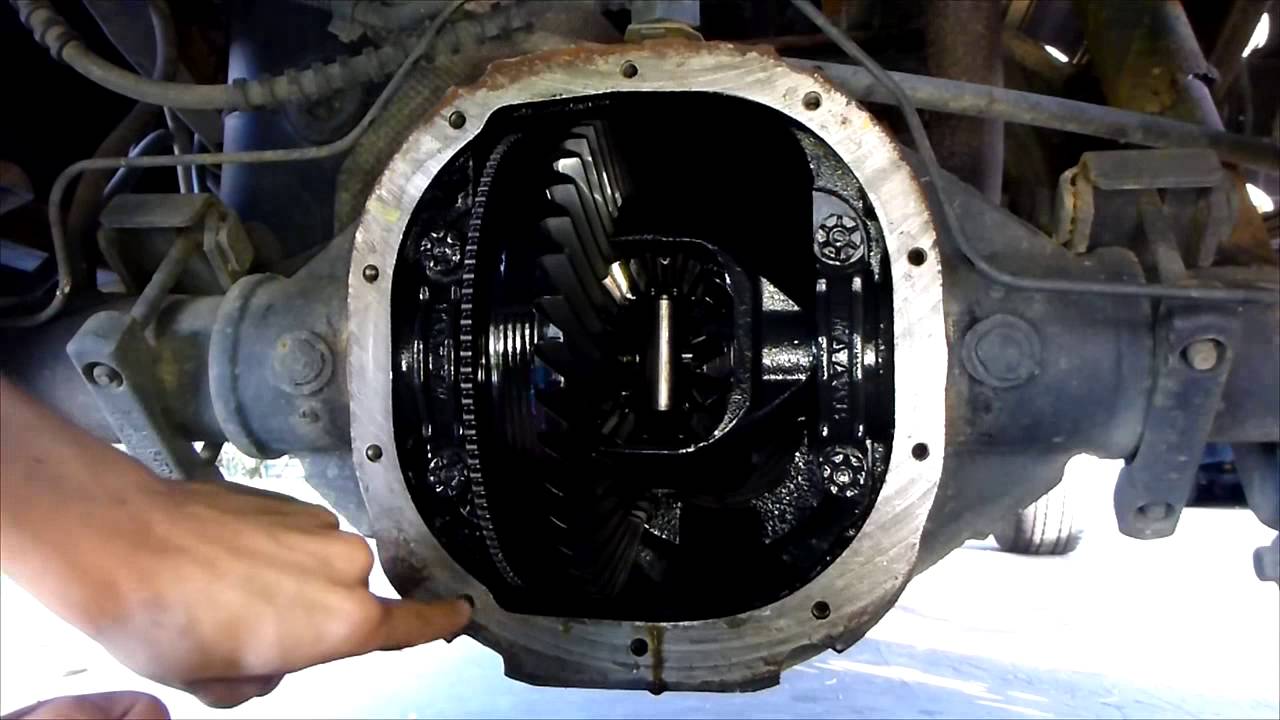

Step 4: Remove Cover and Drain the Lubricant

If you don’t have a drain plug (most older trucks do not) place a pan under the differential and remove the bolts holding the cover, leaving the bottom three bolts still threaded part way in. Pry the pan loose enough so the oil will start to drain. When finished draining remove the cover for cleaning.

Step 5: Clean Housing And Cover

It’s important to look for excessive amounts of metal shavings laying inside the housing or on the inside of the cover. This could be a clear indication of problems coming up in the near future.

Clean the inside of the housing and cover using a spray can of brake cleaner, then wipe it down with clean shop towels. Using a shop light inspect the housing and gears for any cracks, chips or signs of overheating.

Step 6: Remove and Replace the Gasket

It’s important to remove all of the old gasket and silicone so your new gasket will seal properly. You will likely need to use a gasket scraper to remove the old gasket from the housing and the cover. There are spray products for gasket removal available if you are having a hard time scraping it off.

Place small dabs of gasket silicone to help hold the new pan gasket in place. Have a helper hold the pan in place while you start the bolts. Tighten the bolts in a criss/cross pattern so the pan tightens evenly. Torque the bolts to manufacturers specifications which is usually 25 to 30 foot pounds.

Step 7: Fill with Lubricant

About half way up on the center housing you will find the fill plug. Remove it with a socket wrench and extension. Most differentials hold between 2-1/2 and 3 quarts of lubricant.

Its not easy filling the housing as it is at a difficult angle. Cut the tips off of the squeeze bottles and force as much as you can out of the bottle. You may need to combine the remainder of the bottles into one to get it full. You want to be sure you get the rear end completely full.

Step 8: Lower Truck From Jack Stands

Lower the truck to the ground and take for a test drive to warm up the oil. You shouldn’t have any issues but you will want to check for leaks.

Tools And Supplies Needed:

It’s not a long list of supplies and tools, in fact you probably have most of them in your shop already. Check with your owners manual for the correct lubricant to use and if see if you need to include any additives.

- Floor jack

- Jack stands

- Socket set

- Drain pan

- Gasket scraper

- Spray brake cleaner

- Gasket or silicone gasket maker

- Gear oil and additives

- Shop rags

- Small pry bar or large flat screwdriver

Why Does a Differential Need Serviced?

High speed driving and hard driving are reasons for servicing the differential. When trucks work harder the oil gets hotter and will break down sooner, losing its viscosity and the protection barrier.

When I bought my project truck I hauled it to my house on a trailer. So like many of us I had no idea of the condition of the rear end. Before I got it running and took it out on the road I wanted to do a good inspection of the bearings, gears, seals and change the oil.

One of the symptoms that is most commonly associated with bad or failing differential or gear oil is a noisy transmission or differential. If the gear oil runs low, or becomes excessively dirty, it can cause the gears to whine or howl as they turn. The whining or howling is caused by lack of lubrication and may increase in volume as vehicle speed increases. A howling or whining differential or transmission should be inspected as soon as possible in order to prevent the possibility of serious damage.

autoblog.com

The differential housing supports the carrier and the axles. Its function is to deliver the power from the motor to the rear wheels. There are not a lot of parts in the rear end but they are all critical. You’ll want to look over each gear for chips, check the axles for wear areas, and replace the seals and oils.

The outside wheel travels further than the inside wheel when turning a corner. The differential allows the wheels to travel at different speeds to provide equal force to the driving wheels.

Lewis, R. P., and L. J. O’Brien

Every differential contains two differential bearings, two wheel bearings, two pinion bearings, a set of pinion gears, three seals, and two axles. These items must all be properly lubed at all times. Over time the gear oil breaks down losing its viscosity and will no longer protect all of these parts.

How Often Should a Differential Be Serviced?

Typically the service interval for a rear end is between 80,000 and 100,000 miles for normal driving conditions. If your vehicle does towing or hauling the interval will go down to closer to 30,000 miles.

For these reasons you should keep track of how many towing or hauling miles you put on your truck.

How Much Does It Cost To Service A Differential?

| Differential Fluid Change | Serviced by | Cost |

| Midas | $100 to $175 | |

| Napa | $81 to $152 | |

| My mechanic | $75 to $150 | |

| Myself | $20 to priceless |

The cost of having a differential serviced is $75 to $175. The differential fluid costs about $20. The cost of servicing a truck differential varies by where you live and the type of vehicle you are having serviced.

I prefer to do my own service so I can inspect the gears and bearings. If the old oil smells like it has been hot when it comes out– I want to know. Doing your own service gives you a heads up on any future issues.

Final Thoughts

This is an important service that we can do on our trucks in just a couple of hours. I like to know what’s going on inside there with the gears and bearings and the way to do that is to service it myself. I like to do my own servicing on my truck so I get to know it better. After it’s all cleaned up is a good time to paint it even though it is pretty well hidden out of the way. If you want a little bling back there, put a chrome cover on with that new paint. Happy Trucking!

The Tool Box

Heres a cool looking cover for the 12 inch rear end.

Heres a great set of jack stands:

Related Topics:

Can you drive a car with a bad wheel bearing? It is very unsafe to drive with a bad wheel bearing. A bad wheel bearing can cause the wheel to lock up while driving, possibly causing an accident. A damaged wheel bearing also puts a lot of stress on the hub, the CV joint, and the transmission itself.

What sound does a bad wheel bearing make? The sound coming from a bad wheel bearing is a loud hum. It can be hard to diagnose because a bad bearing in the transmission or differential can make a similar sound. Sometimes a bad tire can make a similar sound also. A mechanics shop can put your vehicle on a lift and diagnose the problem by spinning each wheel.

Sources: autoblog.com

popularmechanics.com

Lewis, R. P., and L. J. O’Brien. “Limited SLIP DIFFERENTIALS.” SAE Transactions, vol. 67, 1959, pp. 203–212. JSTOR, www.jstor.org/stable/44547524.