My Current Project: 1972 Chevy C10 Short Box Pickup

I’m currently rebuilding a 1972 Chevy C10 short box truck. I hauled it home on a trailer along with a pickup bed full of miscellaneous parts. I like to stay busy and I like to work on cars and trucks. That combination is the perfect storm for the hobby of car and truck rebuilding.

I’m also working on a 1955 Ford body that is on a shortened 1977 1/2 ton four wheel drive frame. This article will be all about the C10 pickup.

Finding The Right Project

When I started looking for another project, I didn’t really have anything in particular that I was searching for. Budget was a big factor as I set myself the challenge to initially spend around $3000 to $4000. I knew with a budget that size it would make my choices pretty limited.

There are quite a few old trucks close by because we live in a rural area. People used them for farming and ranching. And people around here just like to drive trucks. Lots of guys keep a pickup around just for hunting purposes and to haul trash to the dump on the weekends.

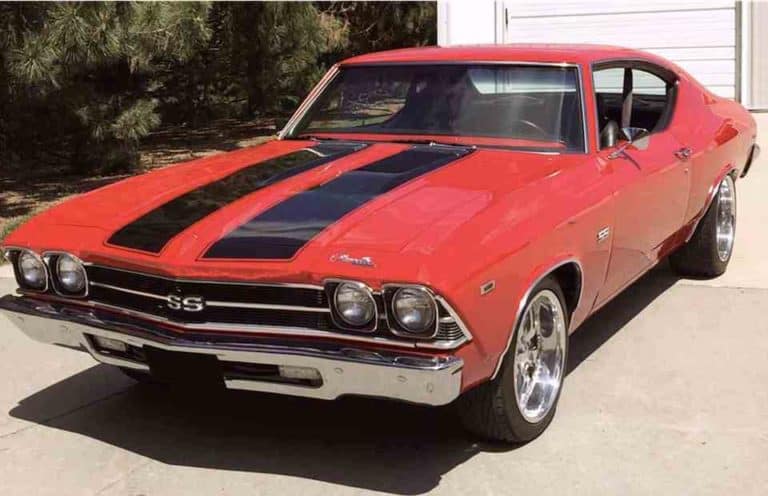

I would really have loved to buy a Roadrunner because I have owned a few of them– then sold them, but I soon found that $4000 wasn’t close to buying even the cheapest non-runners within 300 miles. Camaros, Chevelles– just weren’t going to happen with my limited budget.

I then started to concentrate on pickups. I’ve always liked the Ford F100’s but I had rebuilt a 1955 from the ground up about 15 years ago and wanted to do something a little different.

I like the C10 bodies but didn’t care too much for the long beds and that seemed to be all that was available for sale. They are everywhere around for miles. I can think of 10 or 15 sitting behind houses and farmer’s shops that are in really tough shape within 5 miles of my house. Mostly long beds and in tough shape.

One day at work a friend of mine asked if I had noticed the C10 short box on Craigslist. Sure enough, there was a 1972 C10 shortie that came with a 454/Th400 combination. It was only an hour drive from my house, so that weekend my wife and I grabbed a pile of cash to see if we could strike a deal.

Getting It Bought

Any vehicle that is about four different colors with the engine, transmission and driveline out isn’t too impressive at first sight. The seller seemed like a decent guy who liked to talk and had a lot of information about the truck.

The first thing I did was to look the frame over good to be sure it hadn’t been shortened. Perfect– it was a real shortbox.

The owner was originally from Texas, as was the truck, and he had brought it here with him to Idaho when he moved here for a job. He was in a situation money-wise that he had to fix his everyday driver– and he needed to sell it.

His asking price was $3600 and my initial offer was $2500. Maybe I wasn’t being the nice guy here. He assured me the 454 had been rebuilt in Texas before he left and the TH400 was solid. I could see the block was perfectly clean like it had been through a rebuilders shop, but you just never know.

I knew buying this all in pieces it was an as/is transaction and that is why I started with the low ball price. It would be months before I would have it running so I bought it on the notion that I had maybe a 70/30 chance that everything was good.

It’s probably a little harder negotiating with a guy that has a cute family of kids running around the swings in the yard, and who needed to get his daily driver running. We settled on $3200 which I felt pretty good about and didn’t feel like I had just taken advantage of someone.

I made arrangements to be there the next weekend with a trailer to load it on. I would need to load the engine, transmission, and various boxes of parts into the back of my pickup.

Bringing It Home

At one time in my life when I had a car lot, I owned a car trailer. That’s one of those pieces of equipment that if you keep it you will be loaning it out more than using it yourself, so I sold it. It’s so easy to go into the local Uhaul and rent a trailer for the day and it only costs $50.

I’m fortunate to have a very understanding wife who enjoys an adventure as much as I do. We got the trailer rented and headed north to get my new project.

One of the handiest tools I have ever bought is an electric winch that you can hook to your bumper and truck battery and drag cars up onto the trailer. It was a life saver at the car lot for bringing home dead cars, or cars that broke down while we were bringing them back from the auction.

We got the C10 onto the trailer using the 12 volt winch and loaded the engine, transmission and various boxes of parts into the back of my F150. It was a pretty heavy load but I kept it under 50 miles per hour and it towed home fine.

Unloading And Sorting The Parts

Bringing home a large assortment of parts is like a really good Christmas morning to a car guy. I easily unloaded the truck off of the trailer by letting it slowly roll off the back with the winch letting it out a little at a time. I have a sloped driveway so I did’t want it to take off too fast and roll into the trees.

I again employed the winch in unloading the engine out of the back of my pickup along with a come-long for added stability and extra lifting power as big blocks are around 720 pounds. It all went well and we didn’t need to call 911.

Getting The Engine Started

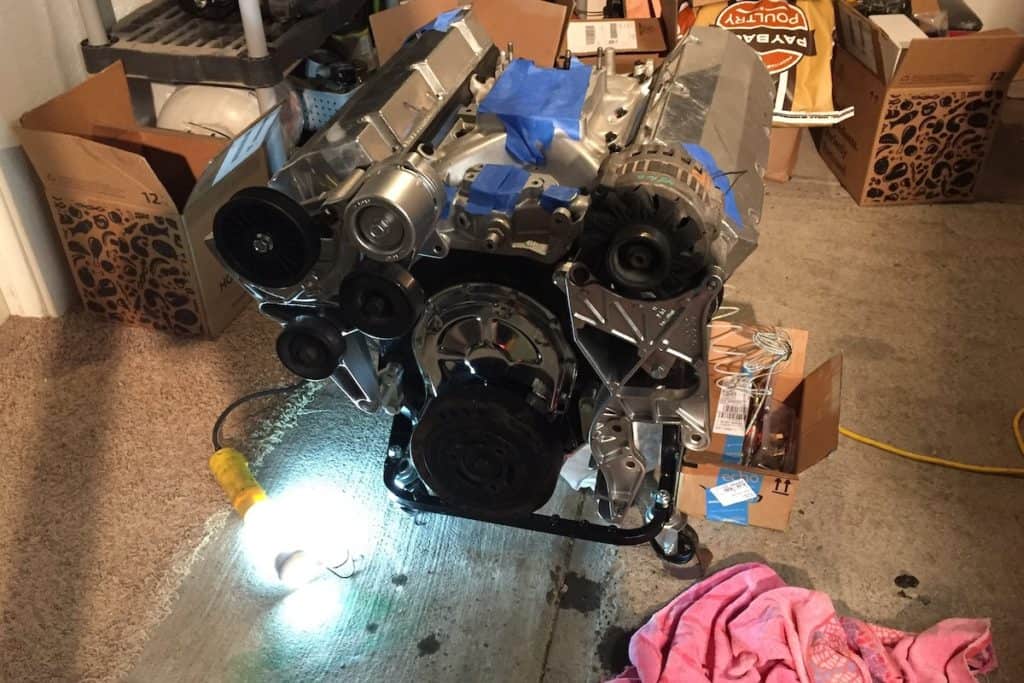

Before I went to all the trouble of installing the engine in the truck I wanted to make sure that it ran. I bought a small engine stand from Amazon for $60 that seemed stable enough to start an engine on. I looked at $500 stands that come with a gas tank, small radiator and a starting bench, but that was way more involved money-wise than I wanted to be.

I mounted the engine– with just a little grinding on the lower part of the engine stand to clear the headers. I rigged up my radiator on some wood blocks and fed it fuel from a gas can that I kept about six feet away from the engine. The wiring is simple and I made a little wooden stand for the gauges and toggle switch for killing the motor. I used a remote start button that worked out perfectly.

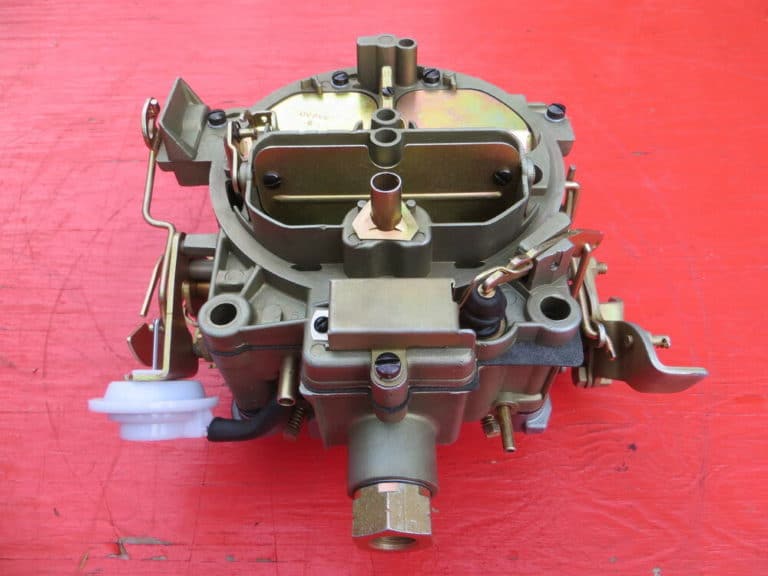

I let it run up to temperature a few times with absolutely no problems. The oil pressure was above 40 at idle and it ran pretty darn smooth. Granted there were a few things I had to deal with like finding a carburetor that would actually work. I ended up trading for a quadrajet that I rebuilt on my garage bench with a $25 kit and it worked fine.

I will probably bench start any engine I buy before installing after doing this one because its fun, interesting and gives you peace of mind. It is certainly a great way to learn about how an engine’s wiring works and it just gets you more involved in your project.

| Body | 1972 C10 Short box |

| Engine | 454 Chevy |

| Transmission | Th400 Chevy |

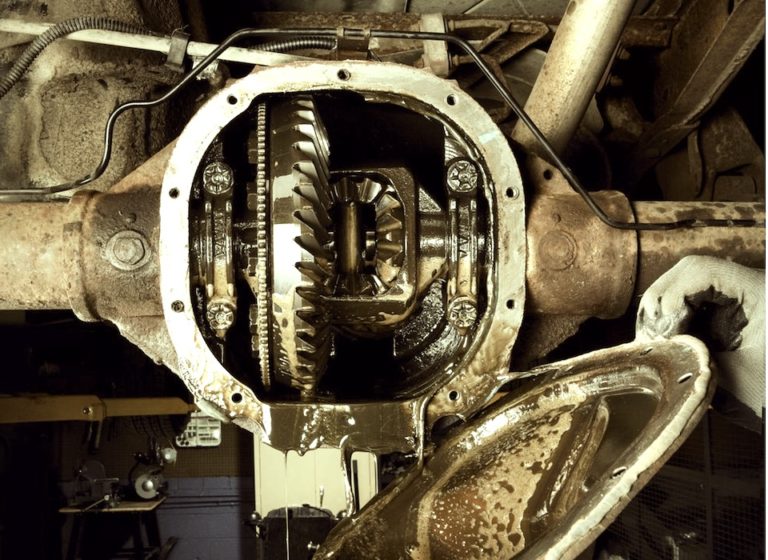

| Differential | Chevy 12 bolt 3.73 ratio |

| Seats | 2011 Arcadia |

Final Thoughts

This whole process was really a lot of fun. Hunting for a vehicle to work on is almost the best part of a new project. A lot of people don’t like negotiating but I find it to be a very interesting part of the process.

The main thing is you shouldn’t think you have to come out the big winner in every negotiation. I’ve witnessed people missing out on some good deals because they felt they had to have the upper hand. Get it bought, take it home and enjoy it.

I plan on working on this truck until I physically can’t anymore. I don’t plan on it ever being finished as I can always find more improvements to be made.

The Tool Box

Here are a couple of tools that will be valuable as you work on your truck. I would always buy the higher rated capacity on any lifting tool.

Related Topics

How much does a big block engine weigh? A big block Chevy V8 weighs approximately 720 pounds. A big block Ford weighs approximately 680 pounds. A Chrysler 392 Hemi weighs 740 pounds.

What car has a v16 engine? The Cadillac V16 engine was a type of automobile engine produced in the 1930s. Cadillac produced two of only three production, gasoline-fueled V16 engine models in history. Both were used in the Cadillac V-16 automobile, the first from 1930 until 1937, and the second between 1938 and 1940.

Sources: Hempson, J., “The Automobile Engine 1920-1950,” SAE Technical Paper 760605, 1976

“The Cadillac Story: The Postwar Years“, By Thomas E. Bonsall