Do Headers Give a Car or Truck More Horsepower?

I have always heard claims of how much horsepower adding headers to a truck will produce. When looking for more horsepower for your engine, are headers an effective way to go?

Headers have individual tubes for each exhaust port that allows exhaust to flow unobstructed from the cylinder head by moving air faster and more effectively. This gives an engine more horsepower for an average increase of 10 to 20 percent.

Putting headers on my trucks is one of the first modifications I make. Let’s see why this is a good idea.

What Exactly Are Headers And How Do They Work?

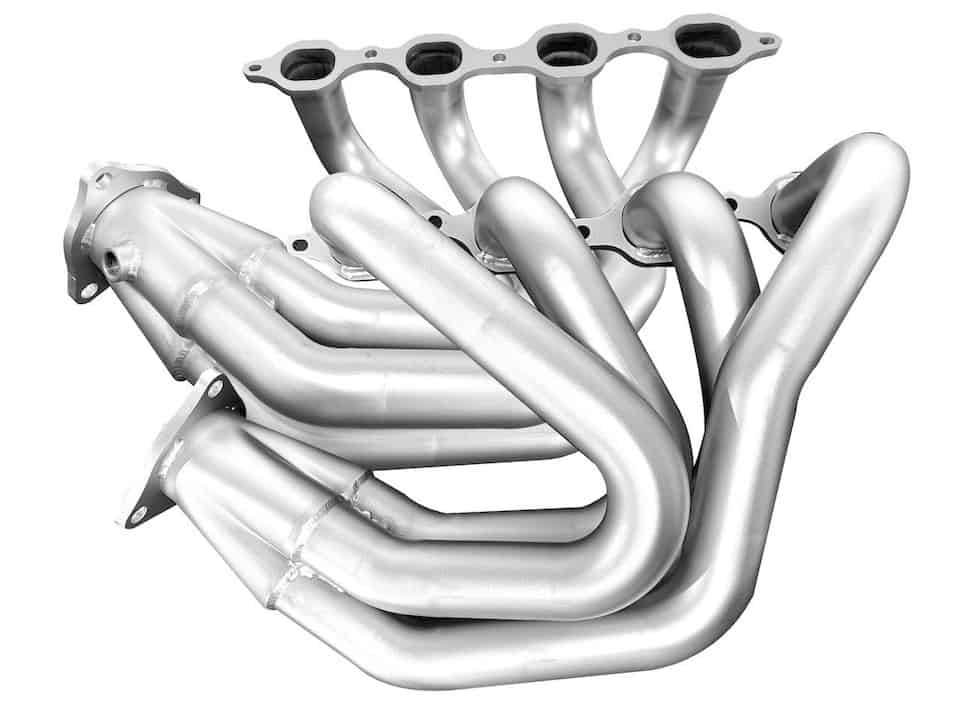

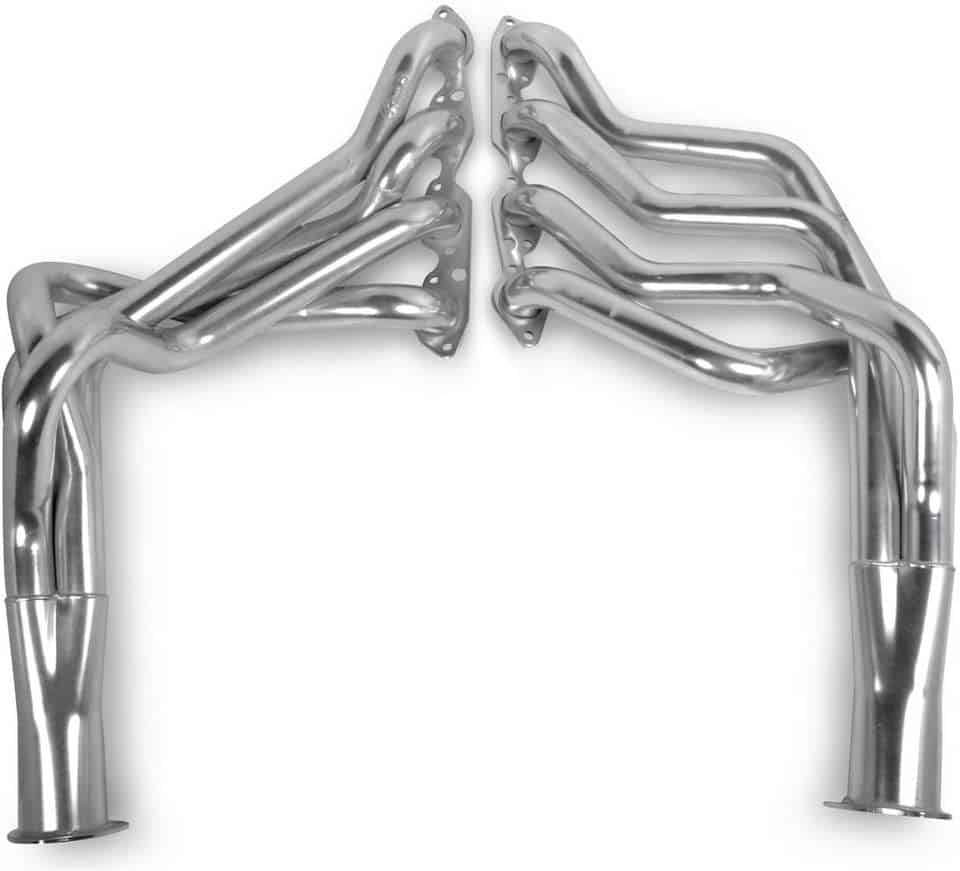

The term “headers” is often reserved for after-market exhaust manifolds. Headers are a system of separate tubes coming from each exhaust port extending to a collector pipe. The collector is connected to the exhaust system.

Stock cast iron exhaust manifolds are what the auto manufacturers use to meet emission requirements while at the same time keeping production costs low. That is why exhaust manifolds are made from cast iron– which is the least expensive way to produce a metal product. This creates the issue of not being as efficient as they could be.

There are two problems with building exhaust manifolds out of cast metal. They have rough interior surfaces which inhibits the exhaust from flowing freely, and they have unequal lengths of exhaust travel when they meet at the exhaust collector.

Even though cast iron exhaust manifolds and headers do the same job, the biggest difference is that a cast iron manifold is a solid cast iron piece that sits across all the exhaust manifolds— whereas a header is constructed of separated tubes for each individual exhaust port and are welded together at a collector pipe– then taken to the exhaust.

. . . you cannot make more power if you cannot exhaust the spent exhaust gases from the combustion chamber. Headers typically do a much better job of efficiently evacuating the cylinder of spent exhaust gas at high engine speeds because they reduce the flow losses of a cast iron manifold.

John Lingenfelter

What Kinds Of Headers Are There?

There are a few different styles of headers on the market today so we will take a look at the most common ones we use on street driven trucks.

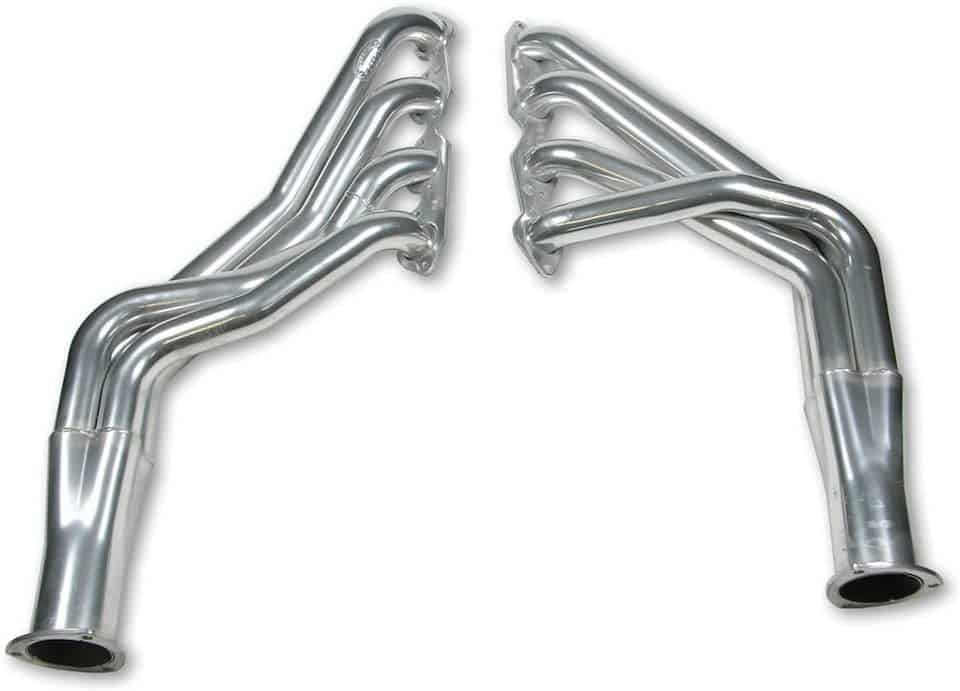

Full length headers compared to stock exhaust manifolds have much longer primary tubes. These primary tubes empty into a collector pipe and form what is called a four in one design.

These full-length headers help produce more overall horse power with more power in the low- and mid-rpm ranges where trucks driven on the streets need it. These longer primaries also help lower the chances of escaping gases getting drawn back into another exhaust pipe.

Shorty headers are made up of four short primary pipes that come together into one short collector pipe. These types of short headers are ideal to be used in situations where there is not enough room for a longer header to clear the frames.

Shorty headers can sometimes work with the remaining stock exhaust components without modification, where full length headers will almost always require some modifications.

Shorty headers don’t always produce as much low- and mid-range power as full or medium length headers. They will provide increased power gains over stock manifolds and can produce higher rpm power gains.

Mid length headers offer some of the benefits of both the full-length and shorty headers. They have longer primaries than the stock manifolds to help produce more low- and mid-range torque and power. The primaries are not as long as full-length headers, so there’s better clearance for lower trucks.

Tri-Y headers merge the four primaries into two slightly larger secondary pipes before merging into one collector.

Most aftermarket headers are made from stainless steel or steel, with standard steel headers being less expensive. Stainless steel headers last longer than mild steel headers in extreme conditions such as the heat in your engine compartment, while they also resist rust. The most common type of header coating is ceramic coating, which provides an added heat barrier.

How Are Headers Installed?

On older trucks and cars headers are very easy to install. Here are some easy steps to follow:

- Use jack stands to safely support the vehicle.

- Remove the stock exhaust manifolds.

- Clean off the head surface so the new gasket can provide a tight seal.

- Coat the new header’s bolt threads with anti-seize compound

- Use strips of masking tape to hold the new gasket in place on the exhaust header.

- Slip the header into place where the stock manifolds were mounted. Install the header bolts and torque to the manufacturer’s specifications.

- Connect the header to the exhaust system.

- Reinstall the spark plugs or any other components that were removed for installation access.

How Much Do Headers Cost?

The price of headers depends on how many cylinders your engine has, the type of finish you want, as well as the brand. It can vary from a 4 cylinder header in the $70 range, up to well over a $1000 for tuned racing headers.

The least expensive headers are plain steel headers. I filtered my search for a 1972 C10 with a 350 motor to give me an idea on different prices.

These are the least expensive I found, for under $150, and surprisingly they are stainless steel with all the necessary accessories included. Some reviewers said they weren’t able to make these fit, though.

Here’s a set of competition ceramic coated headers by Hooker Headers for just over $500 or so, that include all of the mounting accessories. Hooker is one of the most well known brand of header builders on the market.

This is Hooker Headers top of the line ceramic header with tuned ports if you’re needing to spend more money. $1000+

The Proof Is In The Dyno Testing

Chevy High Performance Magazine installed a set of Hooker headers onto a stock 350 Chevy engine. When they put the engine on the dyno they saw an immediate increase of 16 horsepower and a increase of 53 foot-pounds of torque. This example is not a dramatic increase but never the less is a 5-10% immediate jump in power.

Headers can help increase power but the amount in which they can do so depends significantly on the engine type. It’s important that you find the headers best suited for your engine and then make your purchase. The consensus is that smaller-diameter headers are ideal for mild street engines, as they build more torque and midrange engine speeds.

Peak horsepower is important, but with street cars increasing torque even at the sacrifice of some peak horsepower will make the car both more fun to drive and quicker in acceleration.

John Lingenfelter

Final Thoughts

Whether you are looking to add some horsepower, get better gas mileage, or just want your truck to sound cool, headers are in your future. For a few hundred dollars you can add all of this to your ride. Happy Trucking!

The Tool Box

Heres a great tool box with casters so you can roll it to your job. I just got this one for Father’s Day from my wife.

Heres a top of the line impact wrench set that we would all love to have in our tool boxes.

Related Topics

Can you add after-market air conditioning to a classic truck? Yes you can, there are after-market companies that make kits to fit most every vintage auto. Installing air conditioning in a vehicle that doesn’t have air can cost $2,000-$4,000 or more, depending on location and the vehicle’s year, make and model; luxury vehicles can cost even more.

Is it hard to pull a motor out of a project truck? Depending on your mechanical abilities and the tools you have at your disposal it can be quite simple. Here are 8 simplified steps for removal:

- – Drain all the fluids

- – Remove fan, shroud and radiator

- – Loosen power steering pump and slide out of the way

- – Loosen electrical wires and remove alternator

- -Loosen the exhaust manifold and take the bolts off where the transmission attaches to the engine block.

- – Remove the starter and exhaust pipe connectors.

- – Remove all of the transmission connections and the engine mount connections

- – Remove engine with engine hoist.

Sources: Lingenfelter, John, On Modifying Small-Block Chevy Engines, 1996

superchevy.com