What Are Billet Parts and Why Are They So Expensive?

What is billet and billet vehicle parts?

- Billet can be any metal

- Billet does not always make the strongest part

- Billet finishes are brighter

- Billet parts are more expensive

- Billet means a solid chunk of metal

- Billet has 5 different meanings in the dictionary

- Billet parts are very popular

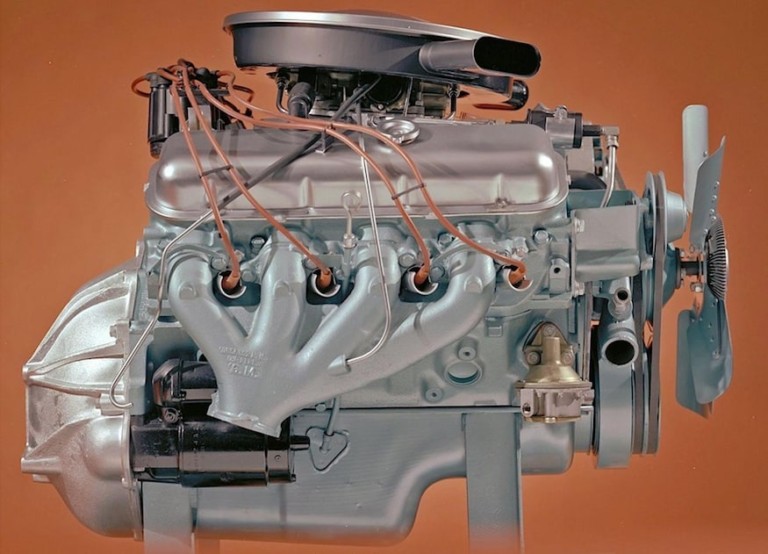

Billet door handles, billet aluminum heads, billet hood hinges. There are many truck parts available to purchase that are made from billet metals. These parts are always more expensive than parts that are cast or forged and are a lot more desired for their shiny, finished look.

We all love to use billet parts on our trucks for their shine, durability and the wow factor. Have you ever wondered how they are made and why they are often stronger, shinier and more desirable?

What Exactly is Billet?

Merriam-Webster has a simple definition for billet, a bar of metal. Billet may also refer to a rolled metal product, the straps to which the girth is buckled on an English saddle, a piece of wooden timber that is prepared to be split, or a rectangular shape on a coat of arms.

Of course the billet we are referring to is a bar of metal that is milled into shapes. When we say a part is billet– like a billet door handle, it means it has been milled and shaped from a bar of metal, not poured into a mold and casted or forged and beaten into shape with a hammer.

Billets can be made of steel, magnesium, iron or lead, but because of its light weight and relatively low cost, aluminum works best for truck part applications. Pure aluminum can be a fairly soft metal, so the aluminum that most billet accessories are machined from is actually a combination of aluminum and other metals.

Products made from billet do tend to be stronger but it’s not necessarily true that a part made from billet aluminum is always the strongest. Calling something billet doesn’t tell you what material it was made from, it just tells you how it was manufactured.

If you made a billet tin transmission and compared it to a transmission made from billet cast aluminum, there’s no question that the cast aluminum transmission would be much stronger than the one made from tin.

Advantages And Disadvantages Of Billet vs Casting

Here is a table of the advantages and disadvantages of making products from billet or cast. As these products are made you have to keep in mind the cost of billet is normally much higher when compared to casting.

| Advantages of billet | Disadvantages of billet | Advantages of cast | Disadvantages of cast |

| Cost effective in low quantities | Costs increase as quantities increase | Cost effective at low quantities | Labor intensive |

| High degree of precision | Some designs are not cost effective to machine | Can produce parts of all sizes | Reduced dimensional accuracy compared to billet |

| Very short lead times | Some designs cannot be machined from solid billet | Capable of producing uniquely shaped parts | Rough surface finish |

| Structurally the parts are stronger | Imperfections or defects in the metal |

How Are Billet Parts Made?

Since billet aluminum parts start their lives as blocks of aluminum or other metals, the finished parts must be carved from these blocks.

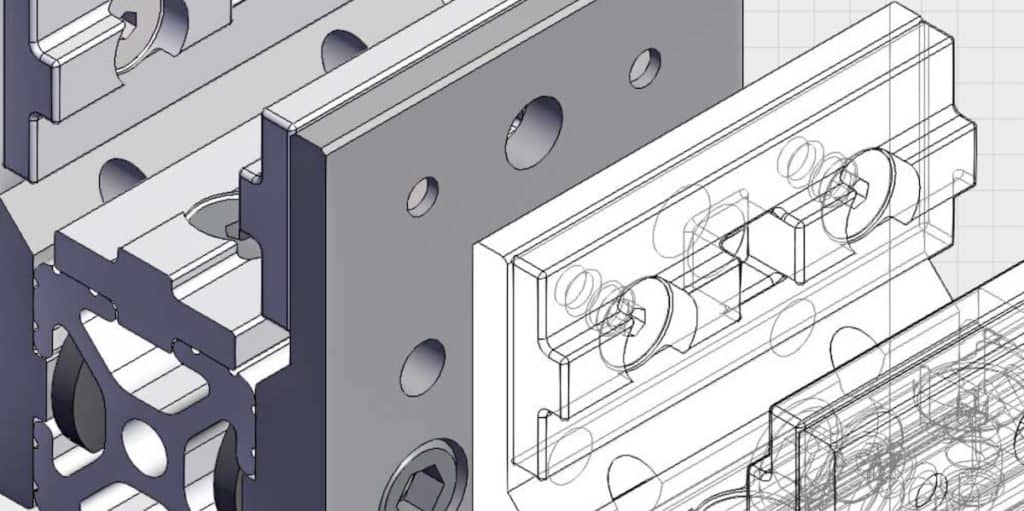

To develop a new billet part, all of the measurements are taken from the original equipment part that is being replaced or from where the new part will be mounted on the truck.

These measurements are then turned into a 3-D wire-frame model on a computer at the factory. This is when the engineer will design the styling touches that influence the look and feel of the part, and then the part can be previewed on the computer screen without cutting a single piece of aluminum.

Once the part design is complete, the engineer creates the list for the cutter tool and the carving order that will create the completed part. Think of it like a sculptor progressively chipping away at a large stone with different tools to get to the finished product.

Most products made from billet aluminum are not exact copies of the original as the designers like to give the parts a little flair. An example of this would be door handles, the billet made handles usually have a nicer look and feel to them.

Why Are Billet Parts More Expensive?

There are a few different factors that make the billet truck parts more expensive than either a cast or forged part:

- When you start with a block of aluminum or other metal there is a lot of the billet that ends up as recycling from the milling process. These pieces of scrap aluminum are worth pennies on the dollar compared to the cost of the original billet.

- The computer controlled machinery that does the milling to precisely cut each part separately is very expensive.

- Since billet parts are so expensive to produce why not just die-cast the parts? Die-cast parts are made from aluminum or other metals poured into a mold, therefore it’s difficult to achieve the same uniform structure, strength, and near perfect finish found in top-quality billet parts.

- New developments in the industry are driving overall production costs lower for some of the more exotic materials. Now, companies are starting to use more forged aluminum, carbon fiber and other non-metallic materials in aftermarket parts construction.

- As time goes by these materials will help the parts become less expensive, and will prove themselves to be even more reliable as the best billet machined aluminum components.

Billet-look or billet-like parts are usually cast aluminum or other metal items dipped in chrome.

Average Prices of Various Parts:

Popular billet parts that you can purchase for your trucks

| Part type | Billet | Chrome on cast |

| 72 C10 Column shifter | $75 | $20 |

| 72 C10 Shift knob | $17 | $500 |

| C10 Door handle pair | $75 | $10 |

| C10 Window crank pair | $80 | $10 |

| Ford F100 door handle pair | $140 | $35 |

| Ford F100 window crank pair | $140 | $35 |

| Ford F100 Hood hinges | $850 | $110 |

Final Thoughts

When you see a truck that has billet parts all through the interior and under the hood, you know the owner has a lot invested in his shine. Billet is more durable with a finer finish than any other options available on the market. Using billet is a great way to put the finishing touches on our trucks and get the desired look that we are after. Happy Trucking!

The Tool Box

While we are talking about aluminum and how strong and lightweight it is, here are a few examples of aluminum shop tools.

Related Topics

When should you repack wheel bearings? Most automotive manufacturers agree that wheel bearing cleaning and repacking should be done every 30,000 miles or once every other year unless your using your truck in harsh conditions, then it should be yearly. The reason for this is that eventually grease loses a lot of its lubricity due to age and heat and eventually breaks down.

What happens when wheel bearings go dry? If wheel bearings are neglected and left to run without grease it can lead to the possibility of the hub and the wheel bolted to it snapping off at the spindle/steering knuckle due to the heat building up and causing friction induced failure.

If you want to try repacking your wheel bearings yourself, see my how-to post here

Sources: Zhang, S. H., et al. “Some new features in the development of metal forming technology.” Journal of materials processing technology. 2004 MacKenzie, D. Scott. Handbook of Aluminum: CRC Press, 2003. Degarmo, E. Paul; Black, J T.; Kohser, Ronald A. (2003),

Materials and Processes in Manufacturing (9th ed.), Wiley