How To Start An Engine On A Stand

For those of you who are building your project truck on a budget, buying a used engine can cut down on a lot of the costs. The $300 to $500 you spend may not buy you the engine that you always dreamed of, but a used engine can get your truck on the road instead of waiting for that dream engine. It’s important to know if these experienced engines are good, and you can check that by doing a bench test on an engine stand.

How do I start my engine on a stand?

- Mount engine in a cradle

- Hook up the radiator

- Hook up a fuel source

- Hook battery + side to starter

- Hook battery negative side to block

- Run a remote starter switch to the starter poles

- Run 12 V lead from battery to distributor BATT side

It would be a lot of work to install an engine in your truck and then discover that it’s bad. Follow along as we learn how to start an engine on the floor and save you that misery.

Let’s Start That Engine

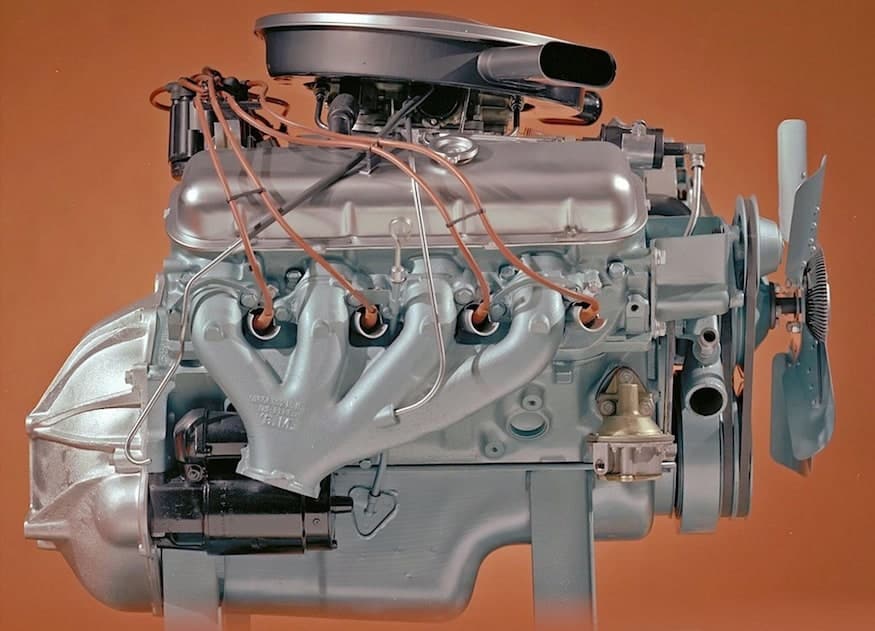

When I bought my 1972 C10 the engine was in the back of the bed and I was buying as/is on the word of the seller. Of course the seller said it was a fresh rebuild that had only been used to drive to church on Sunday. That’s why I wanted to get it running on the floor and do some inspecting before I went to all the trouble to install it.

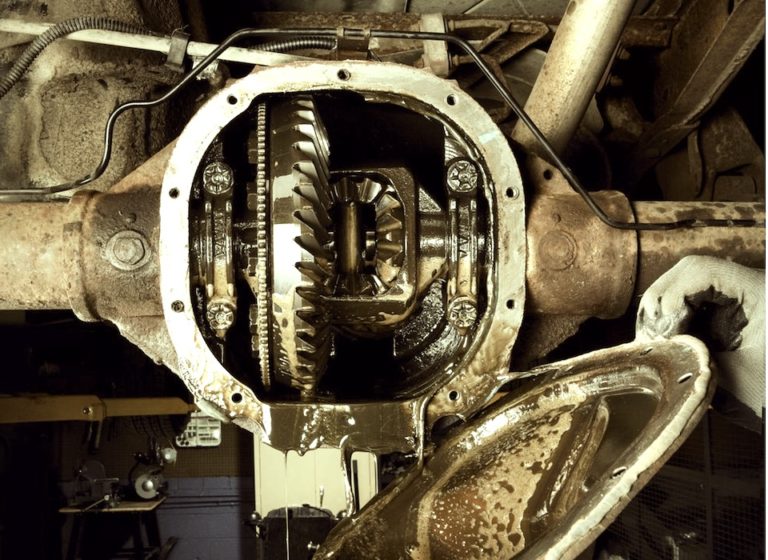

Step 1 – Mount Engine

I got a stand from Amazon, and my engine mounted right into it. When I put the headers on I had to do a bit of grinding on the bottom area on the frame so they would clear, but it was no big deal.

Step 2 – Hook Up the Radiator

If you want to run it for a while you need to be running coolant. It’s best to always have antifreeze in your radiator to keep it from starting to rust inside your motor. You may have to get a little inventive like I did to keep the radiator stable.

Step 3 – Hook Up a Fuel Source

How ever you hook up your fuel source, keep in mind the fumes are very flammable, especially while working in a enclosed area like a shop or garage. Keep your fuel source sealed as much as possible.

Step 4 – Battery Positive Hookup

Hook your battery terminal positive side cable to the big lead on the starter.

Step 5 – Negative Hookup to Block

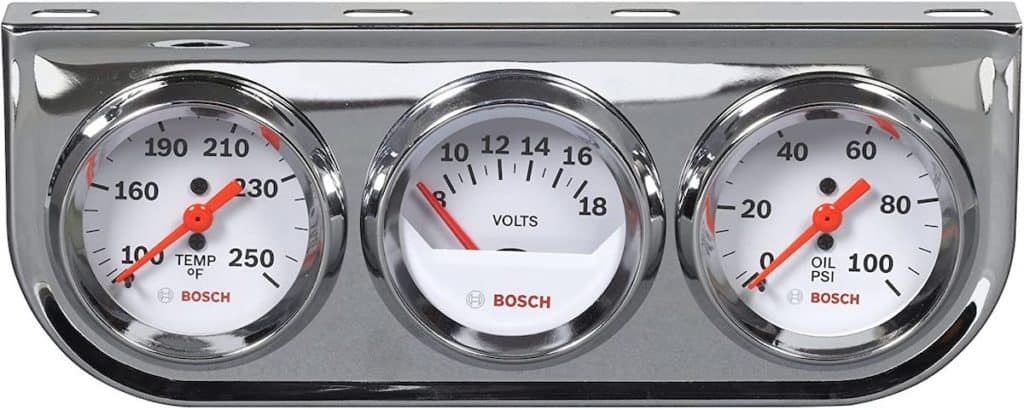

Hook the negative cable to the engine block for a ground. This is a good time to hook up any gauges that you may want to use.

Step 6 – The Starter Button

Hook your starter button clamps to the poles on the starter. You are now ready to start your engine.

Step 7 – Hot Wire to the Battery

Run a 10 gauge wire from the positive battery terminal to the HEI distributor side marked BATT. You can put your on off toggle switch in this wire.

Start your Engine!

When I started my engine for the first time I cranked it for a while to let the oil get all through the engine before it fired. This is a great time to adjust the carburetor and set the timing while you have such good access around the engine. When the engine gets warmed up you will be able to see if you have any oil or antifreeze leaks to repair before you install your engine in the truck.

Is It Safe to Start An Engine Out Of The Truck?

It is perfectly safe but there are a few safety precautions you need to follow:

- Do not use a three wheeled engine stand. Three wheels just aren’t stable enough for when the engine is revved. It could twist it enough from the torque being applied to tip it over.

- Use a sealed gas container to keep any fumes or smells from starting a fire. You can run your inlet gas line into a can and seal it up close to tight with a dry rag and tape to keep the fumes down and it gives the can a little venting. Ideally an old lawn mower gas tank or something like that would work the best.

- If you’re running a fan (it’s not necessary) in between the engine and radiator, it is safer if you can run some kind of shroud at least over the top of the radiator/fan area.

- Make or buy a stand that is stable enough to keep the motor from tipping or flipping. I have heard stories of motors flipping over from the torque but I have never witnessed it. It’s in your best interest to have everything stable and safe.

What Tools And Supplies Will I Need?

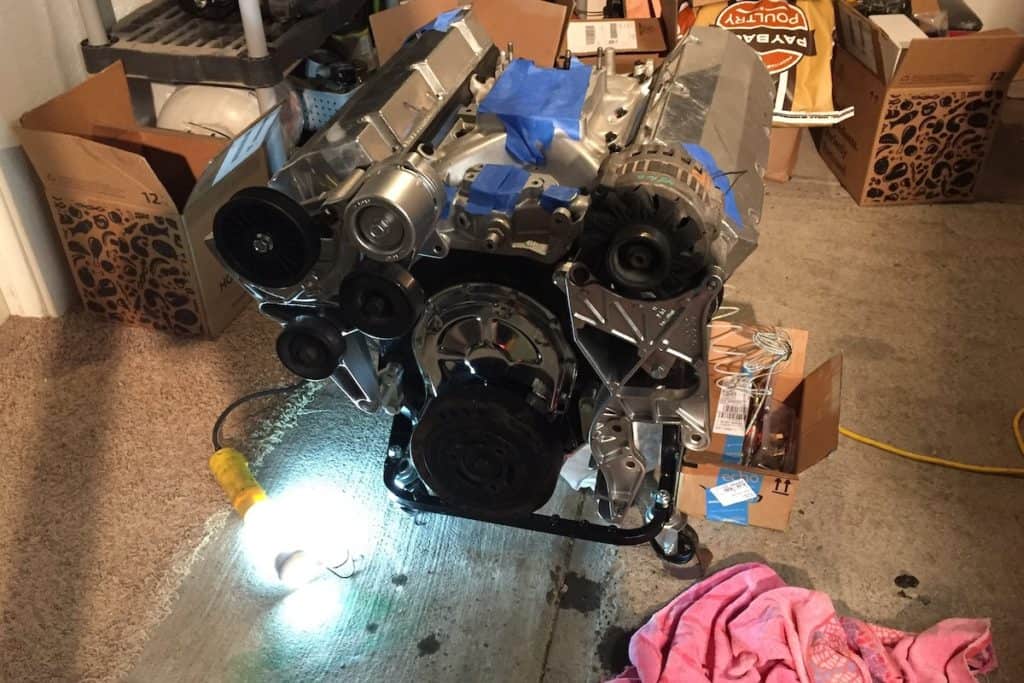

- A good solid engine cradle: On my 454 I used a 4 wheeled cradle and it worked really well for a $45 cradle. There are lots of different types of stands you can use. You can purchase stands that have a console, radiator, gas tank and wiring with all the gauges included. You just set your motor in, hook everything up and start it. There are plans I have seen on forums where you use some 2×4’s and 2×6’s and people say that they work well.

- Radiator mount: If you want to run the engine more than two minutes you will need a way to cool it. I blocked my radiator up from the floor about 8″ and used the radiator retainers from off of my truck to keep it from moving.

- Gas supply: You need a safe way to supply gas to your engine. I used a 1/2 full gas can with a hose going in the top and taped in with just a little ventilation allowed. The next time I will put a lawn mower gas tank or something like it mounted a ways from the motor with the feed coming out the bottom.

- Battery: I put my battery under the stand where I had my gauges and switches mounted so I wouldn’t have to run my wiring and cables very far.

- Remote starter switch: This is something I already use a lot because I work on my truck by myself most of the time and they are really handy to have around.

- Gauges, wiring and switches: I wanted to check oil pressure, temperature and voltage output while it was out of the truck, so I purchased a cheap set of gauges that were mounted together.

- Fire extinguisher: Very important.

- Tools: Your normal tools you have around your shop.

Final Thoughts

Starting my engine on the floor was probably the funnest thing I have done with my truck. I learned a lot about some repairs and leaks I needed to take care of and I also needed to work on the route for my spark plug wires. Then you can paint it up after you see everything works right. Happy Trucking!

The Tool Box

Here’s the engine stand I used, some nice chrome gauges, a handy gas can, and a well equipped top of the line stand. There is everything in between depending on how much you want to spend.

Related Topics

Do wrecking yard engines come with a warranty? Any reputable wrecking yard has at least a ninety day warranty. If the engine fails before ninety days some will refund your money while others will give you store credit on parts. You will not be reimbursed for any labor you or a mechanic have put in on the engine. Where its only a ninety day warranty its a good idea to start your engine on the floor if your truck is not ready for install.

How much do engines cost at wrecking yards? It depends, if you go to a pull it yourself yard or if its already been pulled and is on the shelf. Pull it yourself engines average between $250 and $300 no matter the miles or what it comes out of, with a $50 core charge if you don’t have an engine to give them. Off the shelf wrecking yard engines can run from $500 to over $1500 depending on the engine and how many miles are on it.

Leave a comment:

This post contains Amazon Affiliate links.

top photo courtesy of GM archives